Lithium batteries: storage & shipment

Best practices

Background

One of today’s greatest “headaches” in maritime transit is related to storage and transport of lithium batteries

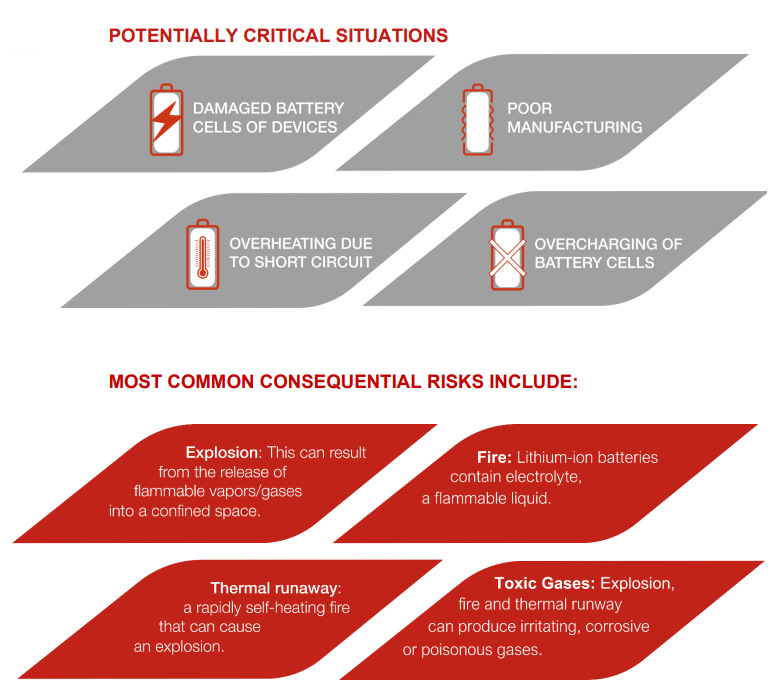

- Lithium-ion battery firefighting is unique, as the fire is fueled by a variable mix of solid, liquid and gaseous substances, depending on the battery’s chemical composition.

- Fires or accidents can break out when the energy stored in lithium batteries is released in an uncontrolled manner. This can be caused by structural and/or technical defects, or by improper use, including mechanical damage to the protective casing, thermal stress caused by external heating, or overload.

- Regardless how it begins, thermal runaway is the biggest fire hazard associated with lithium-ion batteries. Thermal runaway requires active fire protection systems to extinguish the resulting fires and prevent fire damage from spreading to adjacent batteries.

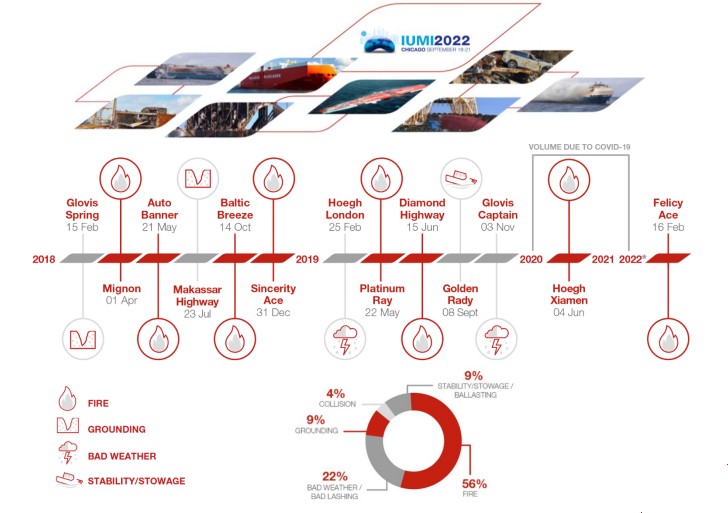

Takeaways from IUMI 2022 Conference

(Chicago September 2022)

Major car carrier accidents as of July 2022 (Ronald Kargl, Munich Re)

Twelve General Safety Rules*

- Follow the manufacturer’s instructions

Make sure to accurately follow any and all manufacturer's instructions, for example the product’s technical data sheets. (#8)

- Train your employees and crew

Employees and/or crew should be trained to handle lithium batteries and made aware that transporting any damaged package is strictly prohibited. They should also know that any and all damages must be reported immediately and/or escalated to a supervisor until resolved. (#5)

- Protect against short-circuiting

Make sure that battery poles are protected against short-circuiting. Request test summaries (TS) from your supplier/manufacturer, certifying that the short-circuit risks have been checked. (#9)

- Check for potential mechanical deformation

Make sure the batteries are protected against any potential mechanical deformation during transport. (#8, #5)

- Monitor light and temperature

Make sure your load is not exposed to direct light, high temperatures or long-term heat sources (including direct sunlight). (#4, #5)

- Check tests using the UN manual as reference

The United Nations Manual of Tests and Criteria sets out a series of design tests that all lithium-ion battery manufacturers must complete. (#8, part III, subsection 38.3, paragraph 38.3.5)

- Establish a BMS (Battery Management System) and verify battery charging

Make sure to set up an electronic BMS and verify the state of battery charging. For transport purposes, the ideal SOC (State Of Charge) is between 30% and 50%, depending on battery manufacturer recommendations, battery size and/or type, anticipated storage time prior to use, and end use. (#9, #8)

-

Monitor stowage management and safety storage

Set up structural and spatial separations as established under VdS 3103 and/or FMD 8-1 storage guidelines. (#2, #3) -

Establish a manual extinction procedure

Set up a manual procedure for initial fire extinction. We strongly recommend you organize an on-site fire brigade and provide the brigade with appropriate equipment and training. (#6, #7, #3) - Implement automatic detection systems

Combine heat and smoke detection (a conventional point smoke detector equipped with an extra temperature sensor) with an alarm system. When possible, install a gas detection method that targets CO2 concentrations. Some areas may need shock / impact & vibration sensors for large format batteries. (#6, #7, #3)

- Set up human detection systems

Establish rotating guard shifts. Guards should perform hand-held IR (infrared) camera testing on each lithium-ion battery pack upon arrival and prior to shipment. Conduct visual inspections for damage, as well as additional inspections conducted with an IR camera to monitor all lithium-ion battery cells every three to four hours. (#6, #7, #3)

- Install firefighting systems

Wherever possible, protect the storage area with a water mist and/or sprinkler system with the addition of solid metal barriers (horizontal and vertical) between each storage bay. If this kind of system cannot be installed, then implement a high-powered, water-based fire protection system in order to ensure rapid cooling. (#6, #7, #3)

#Main Technical Reference Documents

(#1) – IUMI Chicago 2022 – “Car Carrier Accidents”: Ronald Kargl – Munich Re.

(#2) – VdS 3103 2019-06 Lithium batteries.

(#3) – FM Global 8-1 Commodity Classification.

(#4) – US Coast Guard, Marine Safety Alert, Lithium Battery Fire, March 2022.

(#5) – Lithium Battery Guide for Shippers.

(#6) – DNV GL Technical Reference for Li-Ion Battery Explosion Risk.

(#7) – Technical Bulletin CEA 4001 - TB 003LI-ION Batteries.

(#8) – The UN Manual of Tests and Criteria sets out a series of design tests(*9) – Lithium Battery Test Summaries (TS).